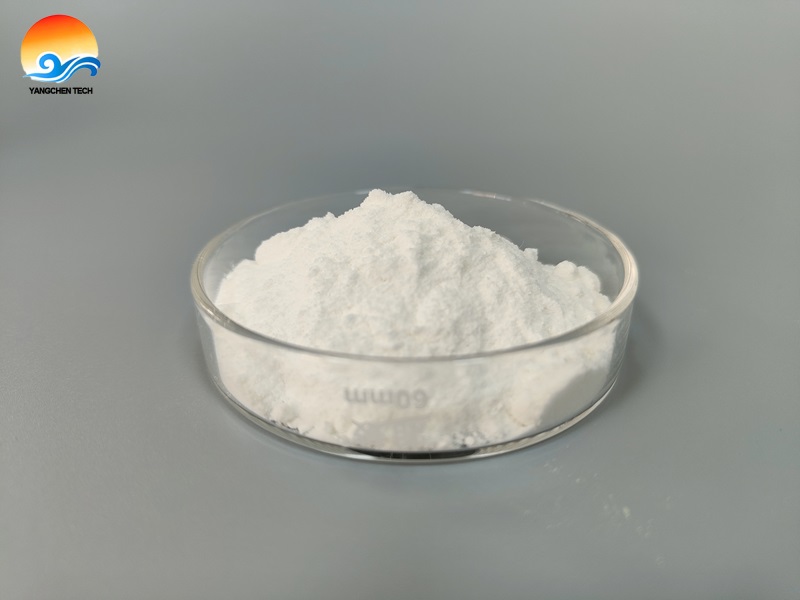

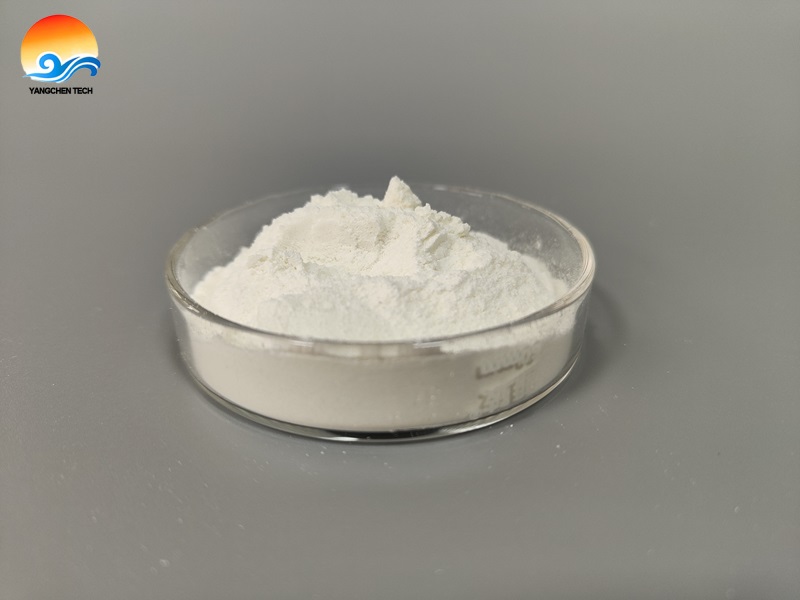

Product Name: Sma Copolymer Powder

N-PMI content: 15%~30% (adjustable)

Uses: Heat resistance Modifier for ABS resin.

Compatibilizer for the Engineering Plastics alloy/ABS (e.x. PA6/ABS).

Welcome Inquiry!

Sma Copolymer Powder manufactured by Yangchen Tech,adding 1% NPMI as a copolymerization monomer in ABS, the heat distortion temperature of ABS resin can be increased by about 2 °C. When 15% NPMI is added to ABS, the heat-resistant temperature of ABS resin can reach 125–135 °C. Compared with similar products, ,our products have excellent heat resistance.

Basic Physical Properties OF Sma Copolymer Powder manufactured by Yangchen Tech

| Test Item |

Test Standards |

Test Data |

| Molecular weight and distribution |

GPC |

Mw=12~16*104.PDI=2.0~3.0 |

| Glass transition temperature/℃ |

DSC |

160~210℃(Adjustable) |

| Initial decomposition temperature/℃ |

TGA |

395-405℃ |

| Density |

ASTM-D792 |

1.00~1.15g/cm3 |

| Appearance |

NG |

Off-white powder |

Key Characteristics of Sma Copolymer Powder manufactured by Yangchen Tech

1.Provides excellent thermal stability, making SMA suitable for heat-resistant coatings and adhesives.

2.Environmentally friendly, meeting modern regulations for sustainable products.

3.Makes SMA highly adaptable for use in solvent-based formulations.

4.Enables efficient formulation of water-based systems, offering improved processing and reduced energy consumption.

5.Balances hydrophobic and hydrophilic properties, creating excellent dispersion and wetting effects in aqueous systems.

Applications of Low Molecular Weight SMA Copolymers Powder manufactured by Yangchen Tech

1.Improves stability and dispersion of pigments in paints, inks, and coatings.

2.Enhances paper surface strength, reducing water penetration and improving printability.

3.Provides high gloss, heat resistance, and low VOC formulations for printed materials.

4.Adds durability, flexibility, and improved water resistance to leather.

5.Used in thermosetting resins for better thermal and mechanical performance.

6.Acts as a surfactant to enhance cleaning power and stability in detergents.

7.Improves compatibility and dispersion of wax in aqueous systems for polishes and coatings.

8.Contributes to protective coatings and solder masks, providing heat resistance and durability.

Packaging:

PE bag lined with PE film, net weight 10kg.

Our warehouse

Manufacturing Workshop of Yangchen Tech

Why choose Yangchen Tech?

1.The annual output of Sma Copolymer Powder ,we can reach 2000 tons per year.

2. With over 30 years of industry experience, our expertise shines through in our products.

3. We have served more than 100 customers from all over the world.

4.Our R&D team provides technical solutions and technical support to meet your specific needs.

FAQ

Q1: Is Yangchen Tech a manufacturer or trading company?

A: We are manufacturer.

Q2: Does Yangchen Tech provide free samples?

A: We are very glad to provide you with free samples for your testing .Feel free to discuss technical issues with our experts

Q3: How to pay for the order?

A: We accept payment by T/T, L/C.

Q4: Does Yangchen Tech provide technical support for customers?

A: Yes, we do. Each customer's application is unique in some ways. Our customized services are designed to better meet your needs. Based on our 30+ years of experience in the rubber additives industry, we can provide technical support services based on your specific needs.

Service Station

Service Station

leave a message

leave a message