HVA-2 Vulcanizer (PDM)

1. What is N,N'-M-phenylene dimaleimide?

N,N'-M-Phenylene dimaleimide (PDM for short) is a chemical substance also known as N,N'-m-phenylene dimaleimide. Its molecular formula is C14H8N2O4, and its CAS number is 3006-93-7. PDM is a sulfur-free vulcanizing agent, so it will not generate sulfides when in contact with copper or other metals, thus avoiding the problem of blackening of metal parts. N,N'-M-phenylenebismaleimide is a versatile compound used in a variety of industrial applications. It is a synthetic organic compound that belongs to the imide family.

In addition to its application in the field of sulfur-free vulcanization, PDM also has a wide range of applications in electrical insulation materials. Due to its excellent insulation properties, heat resistance, corrosion resistance and good mechanical properties, PDM is widely used in the insulation layer of electrical equipment such as cables, wires, motors, and transformers. It not only provides excellent insulation properties, but also improves the heat resistance and corrosion resistance of electrical equipment, thereby extending the service life of the equipment.

In addition, PDM can also be combined with other materials through blending or copolymerization to prepare composite insulation materials with excellent properties to meet the needs of electrical insulation materials in different fields.

N,N'-M-Phenylene dimaleimide is a chemical substance with a variety of excellent properties and has broad application prospects in electrical insulation, sulfur-free vulcanization and other fields.

2. Performance:

- High thermal stability: N,N'-M-phenylene dimaleimide has excellent heat resistance and is suitable for applications in high temperature environments.

- Good electrical insulation properties: It has high dielectric strength and provides effective insulation for electrical components.

- Low volatility: The compound has a low vapor pressure, ensuring stability and preventing evaporation under normal operating conditions.

Technical indicators:

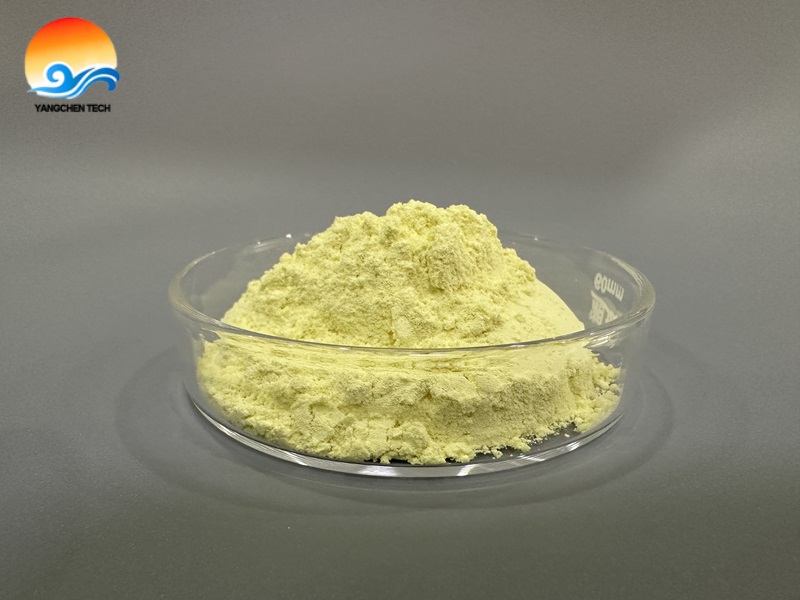

| Appearance |

Yellow powder |

| Melting point |

≥196℃ |

| Moisture content |

≤0.5% |

| Ash content |

≤0.5% |

Dosage: 0.5-1.0 phr as vulcanization retarder. 2-3 phr as a vulcanizer. 1.5 phr to improve compression distortion. 0.5-5.0 phr to increase adhesive strength.

3. Application of N,N'-M-phenylene dimaleimide:

Due to its excellent properties, N,N'-M-phenylene dimaleimide can be used in a variety of industries, including:

- Electronics: Due to its excellent electrical insulation properties, it is often used in the manufacture of electrical connectors, insulating materials and electronic components.

- Adhesives: PDM is widely used as a cross-linking agent in adhesive formulations to improve their bond strength and heat resistance.

- Coatings: HA-8 is used in protective coatings because of its excellent resistance to corrosion and UV radiation.

- Polymer synthesis: It serves as an important monomer and cross-linker in polymer synthesis, helping to develop durable and high-performance materials.

4. Why can N,N'-M-phenylene dimaleimide effectively prevent oxidation of copper wires?

N,N'-M-phenylene dimaleimide has unique properties that help solve copper wire oxidation problems. When used as a coating or added to insulating materials, it forms a protective layer on the copper surface, protecting it from contact with air and moisture. This barrier significantly reduces the oxidation process, thus preventing the copper wire from blackening and ensuring its long-lasting functionality.

5. After-sales service provided by Yangchen Technology:

As a trustworthy supplier, Yangchen Technology is committed to providing comprehensive after-sales services, including:

- Technical support: Our team of experts can provide technical assistance and guidance for the application and use of products containing N,N'-M-phenylene dimaleimide.

- Product Warranty: We offer a warranty on our products, ensuring their quality and performance.

- Quick response: Our goal is to promptly resolve any questions or concerns our customers have and ensure customer satisfaction.

- Product customization: We offer customization options to meet specific customer requirements, ensuring the best fit for their application.

- Timely Delivery: We prioritize efficient order processing and timely delivery to ensure our customers receive their products on time.

6. Reach24H certification

Manufacturing Workshop of Yangchen Tech

Why choose Yangchen Tech?

1.We are the first competent factory manufacturing N,N'-m-phenylene bismaleimide in China, with an annual production capacity of 350 tons.

2. With over 30 years of industry experience, our expertise shines through in our products.

3. We have served more than 100 customers from all over the world.

4.Our R&D team provides technical solutions and technical support to meet your specific needs.

If you have any questions,pls feel free to contact: business@xysjgm.com

FAQ

Q1: Is Yangchen Tech a manufacturer or trading company?

A: We are the first HVA-2 manufacturer in China, with an annual production capacity of 350 tons.

Q2: Does Yangchen Tech provide free samples?

A: We are very glad to provide you with free samples for your testing .

Q3: How to pay for the order?

A: We accept payment by T/T, L/C.

Q4: Does Yangchen Tech provide technical support for customers?

A: Yes, we do. Each customer's application is unique in some ways. Our customized services are designed to better meet your needs. Based on our 30+ years of experience in the rubber additives industry, we can provide technical support services based on your specific needs.

Service Station

Service Station

leave a message

leave a message