CAS:941-69-5

Purity:≥99% (HPLC verified).

Advantages: Chinese manufacturer

Annual production: 2000-3000 Tons

Delivery time:7-15 Days

About Price,WELCOME INQUIRY!

N-Phenylmaleimide-Heat Resistant Polymer Additive is designed for the applications in the plastics, automotive, and electronics industries.N-phenylmaleimide enhances polymer performance under high-temperature conditions while maintaining mechanical integrity. Welcome Inquiry!

Technical Specifications

| Property |

Value |

| CAS No. |

941-69-5 |

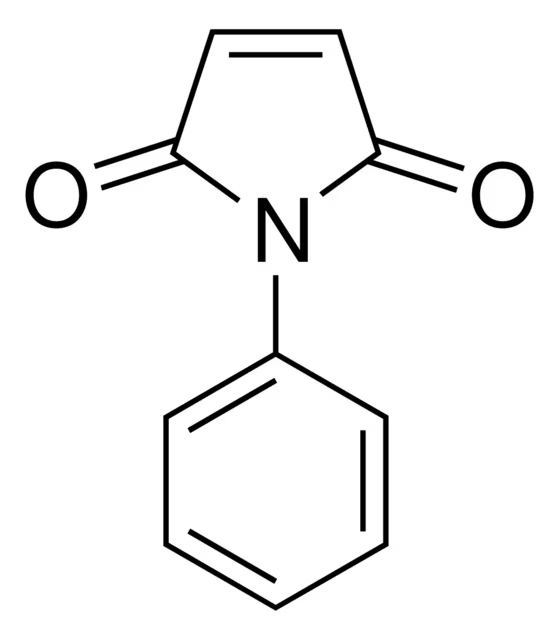

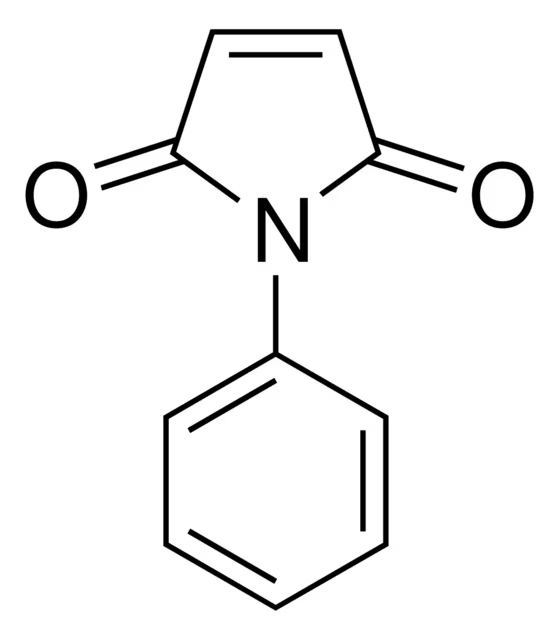

| Molecular Formula |

C₁₀H₇NO₂ |

| Molecular Weight |

173.16 g/mol |

| Melting Point |

85–87°C |

| Boiling Point |

162–163°C (12 mmHg) |

| Density |

1.24 g/cm³ |

| Appearance |

Yellow crystalline powder |

| Solubility |

Soluble in methanol, benzene |

Key Features

1. Exceptional Thermal Stability

Glass transition temperature (Tg) up to 142.6°C when copolymerized, significantly improving heat resistance in polymer blends.

Boosts Vicat softening temperature (VST) by 38.3°C in PVC composites at optimal ratios.

2. Enhanced Compatibility

Uniform dispersion in resins due to tailored molecular structure, ensuring seamless integration without phase separation.

3. Mechanical Strength Retention

Increases tensile strength while minimally impacting impact resistance, ideal for highstress applications.

4. Versatile Applications

PVC Modification: Elevates heat resistance for piping, cables, and automotive components.

Engineering Plastics: Enhances thermal performance in ABS, polycarbonates, and epoxy systems.

Electronics: Used in heatresistant coatings and insulating materials.

5. Quality Assurance

Purity: ≥99% (HPLC verified).

Compliant with ISO 9001, REACH, and FDA standards.

Why Choose Yangchen Tech?

- R&D Excellence: Independently developed production processes ensure consistent quality and customization options.

- Global Compliance: Meets international safety and environmental standards (GHS, SDS available).

- Bulk Supply Capacity: Flexible packaging (25 kg/drum or customized) and reliable logistics for global delivery.

- Technical Support: Dedicated team for application guidance and formulation optimization.

Applications in Industry

- Automotive: Heatresistant dashboards, underthehood components.

- Construction: Hightemperature PVC pipes and fittings.

- Electronics: Insulating films and circuit board coatings.

- Advanced Composites: Polyimide blends for aerospace and industrial uses.

Safety & Handling

- GHS Classification: Toxic if swallowed (H301), hazardous to aquatic life (H400).

- Storage: Keep sealed in a dry, cool environment (room temperature recommended).

- Certifications: MSDS, TSCA, and EPAcompliant.

Ordering Information

- MOQ: 25 kg (customizable for bulk orders).

- Lead Time: 2–3 weeks after confirmation.

- Payment Terms: T/T, L/C, or negotiated terms.

Our Warehouse

Service Station

Service Station

leave a message

leave a message